RESEARCH &

DEVELOPMENT

RESEARCH & DEVELOPMENT

Defence & Aerospace, University Labs, Automative, Medical, Pharma

Pressure Measurement Application for R&D:

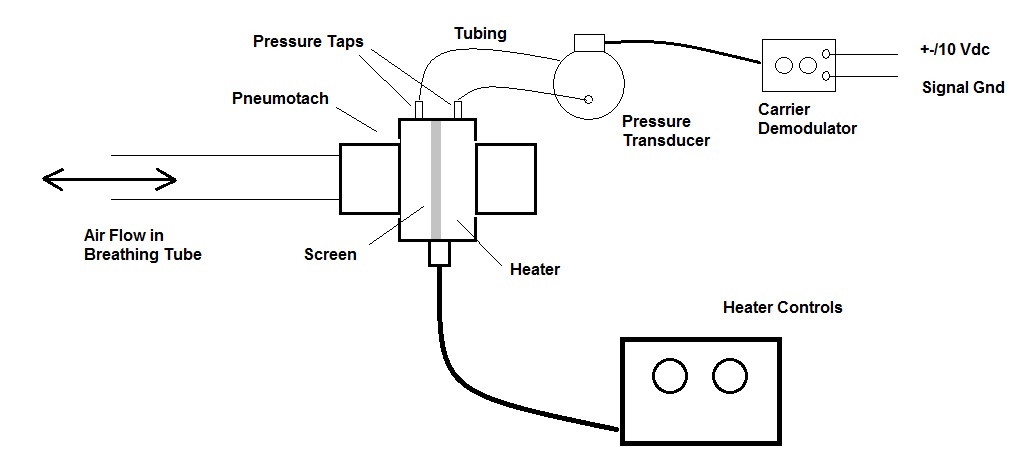

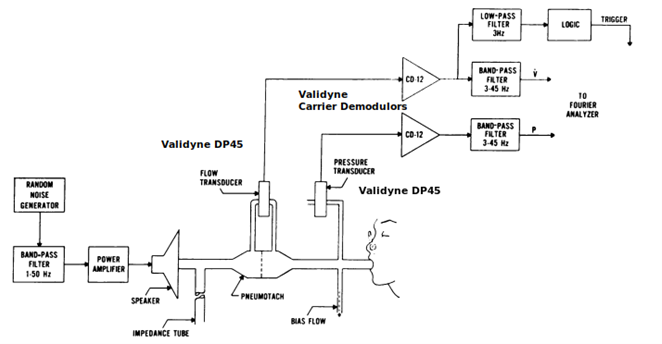

Gas Flow Measurement

Benefits

- Multi-Gas functionality: support for 90 different gases and gas mixes.

- Multi-Parameter functionality: Mass Flow, Volumetric Flow, Gas Pressure, and temperature.

- “User-Defined Mixture” functionality allows to create and store of 20 • custom gas mixes with up to 5 different gases each.

- Optional Modbus RTU network interface with isolated RS485 transceiver.

- User programmable solid state relay with latch option.

- Universal 12-26 Vdc power supply input.

- Local high contrast OLED (optional) graphic display with joystick control.

- Free, easy-to-use configuration and calibration software (RS-232/RS-485)

- Programmable setpoint table with ramping up/down capability up to 16 steps.

- Standard accuracy ± (0.5% RD + 0.2% FS).

- 200 to 1 turndown ratio.

- Quick Response time (< 20ms) for DPM and (100-150 ms) DPC series

- Two programmable mass flow rate totalizers.

- High, Low, or In Range Alarms with preset action delay for Mass Flow, Temperature, and Pressure.

- User programmable mass flow rate Pulse Output (via SSR).

- Extensive Self Diagnostics with status LED or OLED indication.

- All 3 user-selectable analog input and output interfaces are standard: 5Vdc, 0-10Vdc, 4-20mA.

- Two user-selectable digital communication interfaces (RS-232 and RS- • 485) are standard.

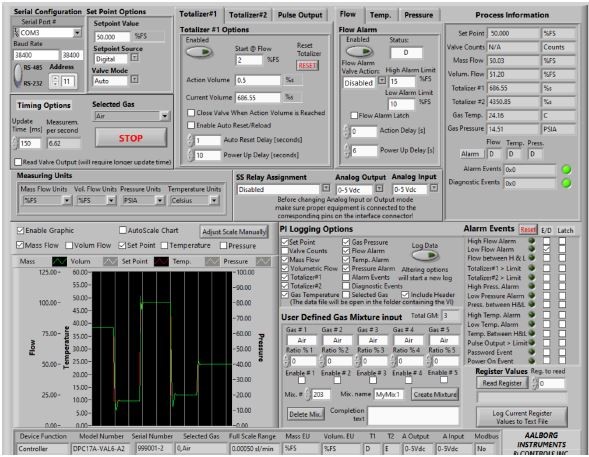

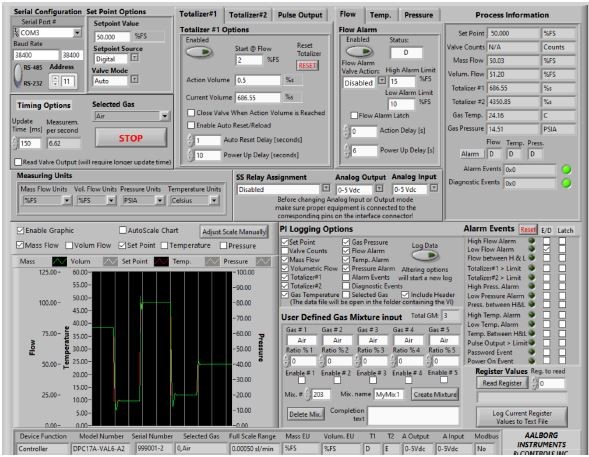

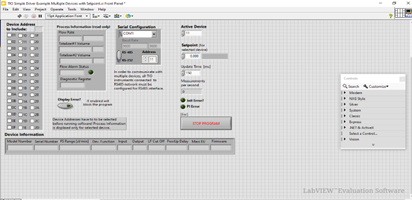

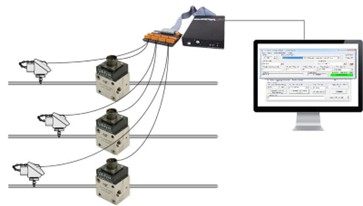

LabVIEW INTERFACE SOFTWARE FOR MASS FLOW METERS/ CONTROLLERS ACQUISITION SYSTEM

- MFC’s Connectivity with Software using serial communication

- Data Storage & Control capability through software

- MFC configuration, setpoints, Totalizer, and control functionality

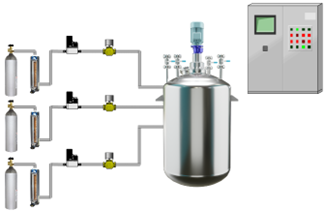

CUSTOM SOLUTION WITH SENSOR, DAQ & SOFTWARE

- Gas Mixing, Flow Measurement & Control Solution

- Liquid & Flow Measure & Control

- Pressure & Temperature Measurement

- Data Acquisition and Reporting

- Control Panel with Data Storage & Software

SCADA SYSTEM

- OPC to Core, 64 Bit SCADA

- Self-service dashboard & Control

- Advanced Graphics in 3D visualization

- GEO Mapping with Real-Time Data

- Asset Management and Analytics

- Trend Charting, Alarms & Events

- Customized Reports

- Connects SAP, Oracle, SQL, Flat Files, Databases and ERP

- Frameworks can be Installed on Premise, VM or Cloud