Instrumentation

Flow Measurement

Thermal Mass Flow Meter / Controller

- Flow ranges starting from 0 to 1000 SLPM

- LCD display and Serial Communication

- sensor and Totalizer option

- Rugged metallic body (Aluminum/SS)

- Maximum pressure of 1000 PSIG (70 Bars)

- Leak integrity 1 x 10-9 SCCS of helium

- Analog output, Totalizer, Communication

- Store multiple gas calibration

- ±0.5% and ± 1% FS accuracy with NIST traceability

Turbine Flow Meters

- Robust, compact design

- Accuracy of less than +/- 0.05% typical

- Excellent speed of response time 3-4mS

- High turn-down capability, up to 100: 1.

- Standard pressure capabilities up to 5000 PSIG.

- Linearity <0.10% with linearizing electronics

- Excellent repeatability, less than +/- 0.05%.

- Extensive primary standard NIST trace calibration capability

- High shock and vibration proof

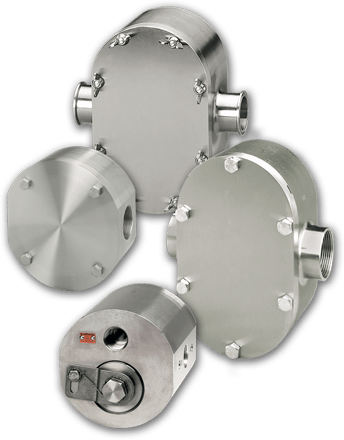

Positive Displacement Meters

- Line Size: 1/16 to 2”

- Very High Viscosities Range: Up to 1,000,000 cP+

- Repeatability: ±0.05% to ±0.1% of rate

- Housing, cover and bolts are 316 SS

Differential Pressure type Flow Transmitter.

- Accuracy : <+0.5%F.S(Typical); <+0.25%F.S(by customized)

- Temperature compensation: 0c ~ 50c

- Output : 4-20mA,0-5V,0-10V,l2C,RS485…

- Electrical Connection: Fixed cable and water proof IP67(HPT700-s); Terminal Box DIN43650 IP65(HPT700-H,HPT700-G)

- Pressure Type : Differential Pressure(Gauge Type)

- Response time:<10ms

- Certificate : ExiallCT6 and CE Certificate

- Water Proof : IP65 to Ip68 Optional by model

Magnetic Flow Meters

- Matching Accuracy:0.5%

- Damping time constant : Continuous Variable from 0~100s(90%)time grading optional.

- Protection class: IP65

- Communication: Optional RS232C or RS485 serial communication interface, HART communication protocol.

- Loss of power: The internal design of the instrument has a power-off clock, which can store 16 power-off records(10 years)(need to be customized)

- Explosion–proof mark: Ex d ia [ia a] q LLC T6 Gb

- Main power : AC220V 50HZ/DC24V/DC12V/3.3V battery Power supply

- Counter : Forward total , reverse total

Ultrasonic Flow Meters

- Linearity: 0.5%

- Repeatability: 0.2%

- Accuracy: +1%

- Type: clamp-on type

- Pipe Size: 32-6000mm

- Supply voltage: AC220V or DC24V

- Powerful Recording Function, last 64days/64month/5years

Rotameter

- Flow ranges: 0 to 1000 LPM

- Calibrated accuracy: ±1% FS

- Brass, Stainless steel, and PTFE meters

- Rigid compact construction

- Multitube configuration for mixing or separation

Sensors

Current

Our sensors include current transducers, current transformers, and current shunts in various inputs. Our product offering includes fixed or split-core models for easy installation.

Temperature

- Pressure range: 0-5Kpa……40Bar

- Output : 4~20mA, Hart Protocol

- Display: LCD

- Power Supply: 12VDC~36VDC

- Pressure Port: M20*1.5

- Accuracy:0.075%F.S

- Working temperature: -30c~+400c

- Certificate : CE,Exiall CT6 Ga, ATEX , RoHS

Shaft-Mount Encoders

Shaft encoders in both flange mount and servo mount styles and light to heavy-duty models with single or bi-directional output capability.

Thru-Bore Encoders

Thru-bore encoder offering includes various mounting options and shaft hole diameters to fit your application. The range also includes models with single or bi-directional output capability.

Length

These sensors are perfect for full contact measuring, whether used for counting or speed indication. Select from our miniature, general or heavy-duty models, all of which are available with various wheels and mounting brackets.

Proximity

Proximity sensors detect the presence of metal objects which come within range of their oscillating field and provide target detection to “zero speed”. We offer various sizes and diameters to meet many applications.

Magnetic

These low-cost sensors are ideal for speed sensing applications. Used commonly with sensing gears, we offer various sizes for your application whether you need a threaded or non-threaded model.

Pressure Measurement

Pressure Transducer

- Absolute / Gauge / Vacuum / Differential Pressure Transducer

- Rugged and Durable High and very low-level pressure sensor

- Accuracy up to ± 0.05% and 4 to 20 mA or 0 to 5 VDC output

- Suitable for temperature from -196 to 200 Deg C.

- Variable reluctance pressure sensor capable of range change

- Ultra-low & Ultra High line type pressure transducer

- FM, CSA, ATEX & IEC, SIL, Intrinsically Safe, Hazardous, and

- Explosion-proof approvals

- USB interface, HART, CANbus interface and RS 485 communication

- Airworthy / Marine / Transportation / Railway / Rugged application / Cryogenic

Smart Pressure Transmitter

- Pressure range: 0-5Kpa……40Bar

- Output : 4~20mA, Hart Protocol

- Display: LCD

- Power Supply: 12VDC~36VDC

- Pressure Port: M20*1.5

- Accuracy:0.075%F.S

- Working temperature: -30c~+400c

- Certificate : CE,Exiall CT6 Ga, ATEX , RoHS

Differential Pressure Transducer

- Accuracy : <+0.5%F.S(Typical);<+0.25%F.S(by customized)

- Temperature Compensation : 0c ~ 50c

- Output : 4-20 mA, 0-5V,0-10V,I2C,RS485…

- Power Supply:7~30Vdc,8~30Vdc,15~30Vdc,7-30Vdc

- Electrical Connection : Fixed cable and water proof IP67(HPT700-G) Terminal Box DIN 43650 IP65(HPT700-H,HPT700-G)

- Response Time : <10ms

- Pressure Type : Differential Pressure(Gauge Type

- Certificate: ExiallCT6 and CE Certificate

- Water Proof : IP65 to IP68 Optional by Model

Temperature Measurement

RTD

- High accuracy 100 Ω Class A DIN platinum element

- Measure temperature up to 230°C (450°F)

- 0.24″ (6 mm) diameter, stainless steel probe

- Steel braided, neoflon PFA insulated lead wires

- 20′ Cable

- Strain relief spring

- Ideal for use in pressure vessel applications, 172 bar (2500 psi) maximum

Thermocouple

- Probes for surveys on machines and small plants

- Flexible probes with mineral insulation MgO

- High-pressure probes with interchangeable insert

- High temperature probes with metal or ceramic sheath

- Accessories: sliding threaded fittings, wells, and flanges

- Compensation cables

Head Mount Temperature Transmitter

- HART protocol & 4-20 mA output

- Dual universal input

- ATEX and S.I.L. certification

- Mathematical functions

- User calibration & Custom linearization

- Sensor burnout detection

Signal Conditioner

Frequency Input

Voltage and Current input value from 0.1 Hz to 25 KHz with 0.1% accuracy. Two separate input, external push button. Easily configured using a seven position DIP switch, rotary switch and/or push-button Temperature Input Process Input.

Process Input

Programmable process calibration, signal simulation, password protection, error diagnostics. Generates frequencies from 0.001 to 25000 Hz. Universal AC or DC supply.

Temperature Input

Voltage and Current input value from 0.1 Hz to 25 KHz with 0.1% accuracy. Two separate input, external push button. Easily configured using a seven position DIP switch, rotary switch and/or push-button Temperature Input Process Input