Automotive

FLOW MEASUREMENT SOLUTIONS

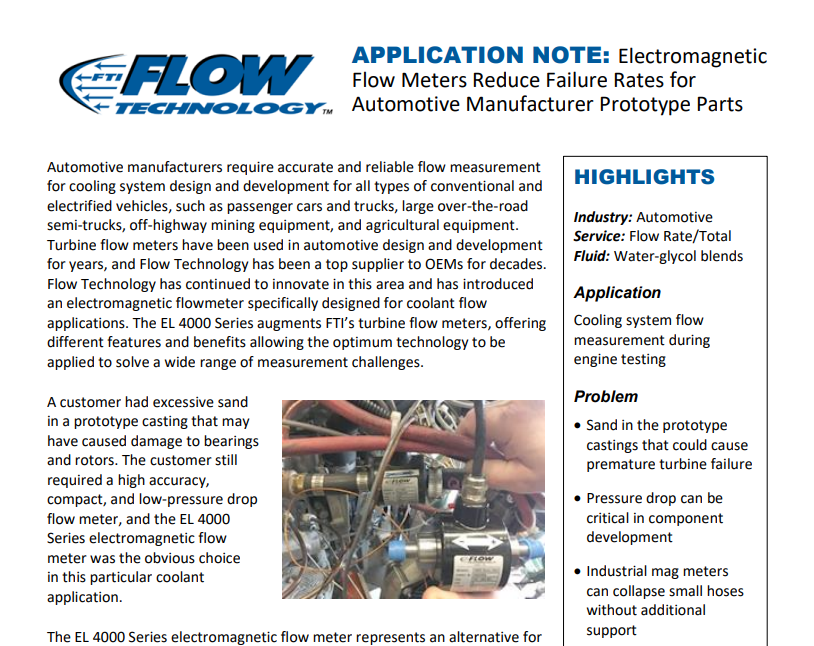

From the research labs of the “Big Three” Detroit automakers, to test tracks around the world, automotive industry leaders rely on Flow Technology to meet their most critical flow measurement requirements. Our Mil-Standard and ANSI-approved flow metering solutions have been utilized by a host of major automotive-related companies.

APPLICATIONS

PRESSURE MEASUREMENT

- Customize to meet your needs

- Measurement & industrial grade accuracy

- Re-rangeable pressure sensors

- Rugged form factor

- AS9100D & ISO 9001:2015 certified

- Fast lead times

- Large or small quantities

- Excellent customer support

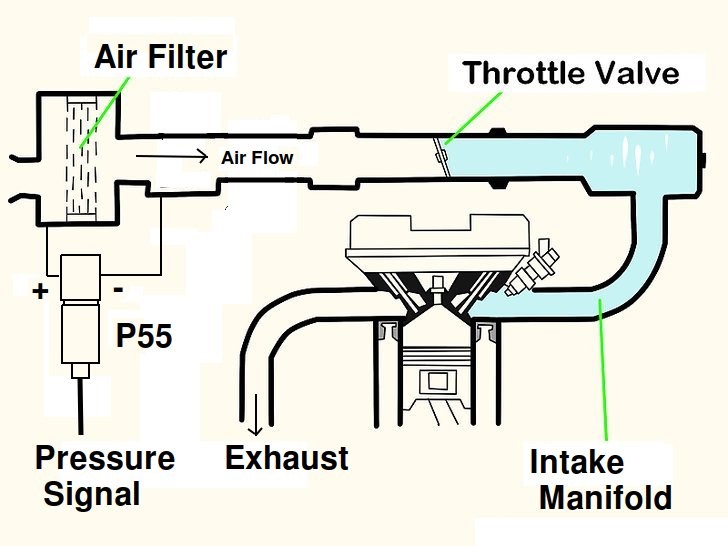

Engine Air Filter Pressure Drop

Automotive engines require a lot of air as part of the internal combustion process. Anyone who has lifted the hood on their automobile knows that the air coming into a vehicle engine is filtered to keep out road dust and grit from entering the engine cylinders.

Car Door Seal Testing

We sometimes notice that when we get inside a car there is a short pressure rise inside the cabin when the door is slammed. We feel this as pressure on our ear drums.

Engine Test Cells

Automotive engines require a lot of air as part of the internal combustion process. Anyone who has lifted the hood on their automobile knows that the air coming into a vehicle engine is filtered to keep out road dust and grit from entering the engine cylinders.

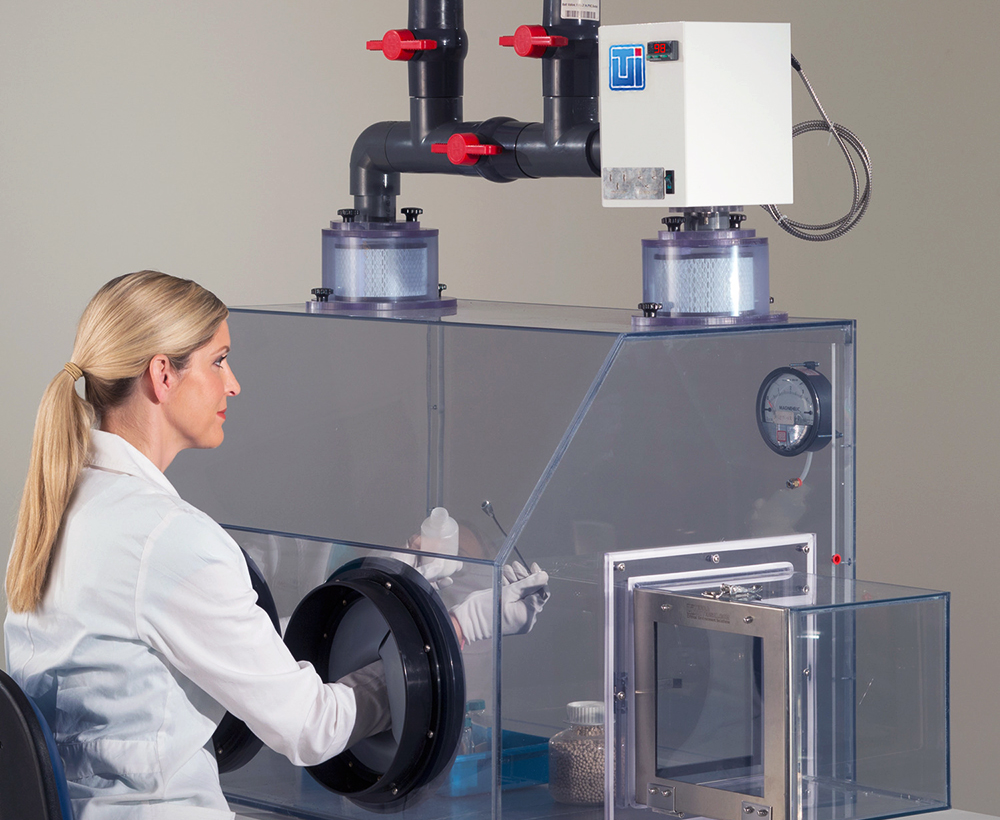

Reducing Glove Box Filter Costs

The handling radioactive materials must be done in glove box. A glove box is a clear plastic enclosure with rubber gloves attached to the sides so that an operator can handle the material inside the glove box, but air and radioactive dust are not allowed to escape.

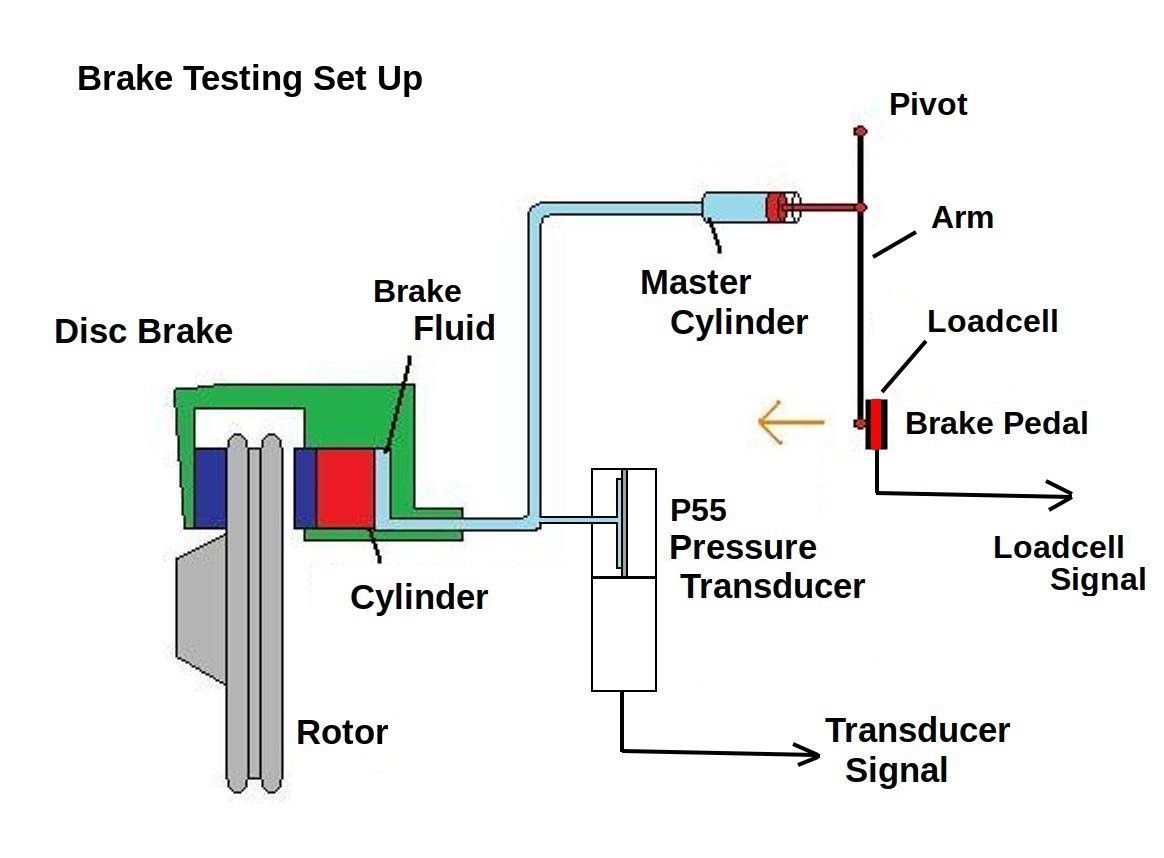

Vehicle Hydraulic Brake System Testing

Automotive braking systems are obviously very important and must be thoroughly tested prior to production. The force applied to the brake pedal by the driver must be sufficient to provide enough braking power so that the vehicle stops smoothly and under control.

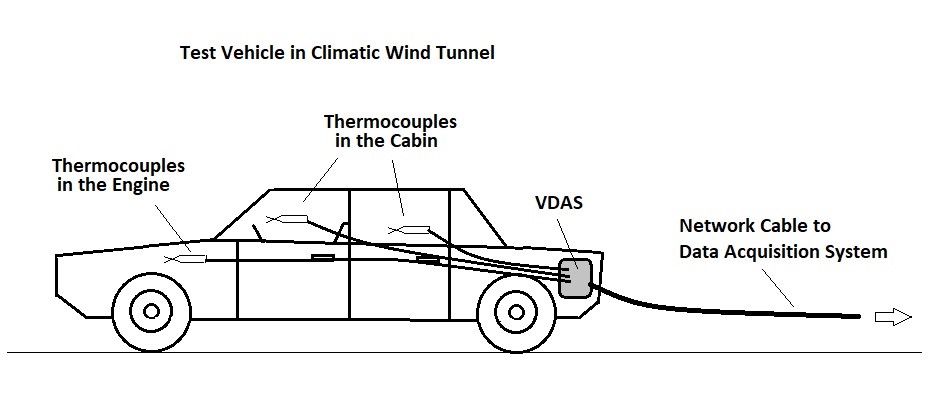

DAQ Used in Climatic Wind Tunnel for Vehicle Testing

A new model automobile must be thoroughly tested in climate extremes before it is put into production. Will the heater keep the passengers warm in a blizzard? Will the cabin be cool enough in the desert summer?

DATA ACQUISITION

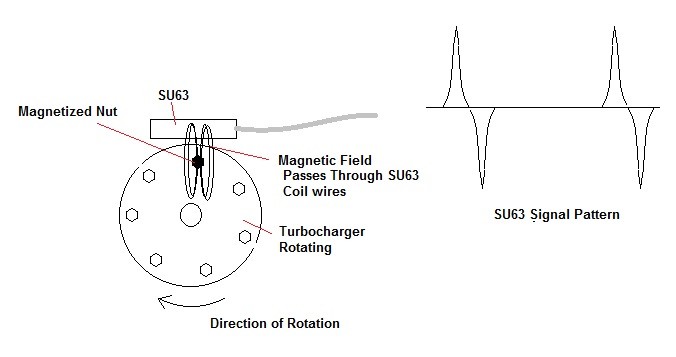

HOW THE SU63 SPEED PICKUP WORKS

The SU63 Speed Pickup is a device designed to be used to sense the speed of turbochargers. A turbocharger rotates very fast – some 10,000 rpm or more, and standard sensing techniques for measuring the speed often fail in the conditions around the vehicle engine. This application note describes how the SU63 senses the very fast turbocharger rotation and how the signal is developed.

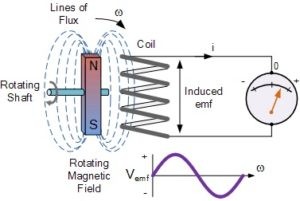

The SU63 is simply a coil of wire mounted on a flexible core and with a cable for making the signal connections. The SU63 is completely passive – it does not require power and generates a signal only in the presence of a moving magnetic field.

Here is how the SU63 develops its output signal:

A rotating permanent magnet, whose magnetic field sweeps through the SU63 coil will develop an induced emf that is expressed as a voltage. As the field sweeping the coil changes in strength and direction as a function of the magnet rotation, the voltage generated varies accordingly. The emf signal amplitude is proportional to the rate of change of the magnetic field in the coil.

In practice, a bolt head or nut on the moving shaft of the turbocharger is magnetized by leaving a strong permanent magnet attached to the part overnight. The SU63 is placed such that the magnetic field from the part will sweep through the coil as the turbocharger rotates. The closer the coil is to the moving part – and the stronger the magnetic field – the better the voltage signal will be from the SU63.

Of course, part of the time the magnetized part will be far enough away from the SU63 so that no signal is developed. But as the part passes by it will generate a kick in the coil that can be counted by electronics connected to the SU63. As the turbocharger spins faster, the signal will decrease in duration but increase in amplitude.